Pilot Freeze Dryer WK-200F 2.25m² 30kg/batch -80℃

Pilot Scale Freeze dryer series WK-200F

Product introduction:

Vacuum freeze dryer is widely used in medicine, pharmaceutical, biological research, chemical industry and food and other fields. The freeze-dried articles are easy to be stored for a long time. After adding water, they can be restored to the pre-freeze-dried state and maintain their original biochemical characteristics.

WK-200F(silicon oil heating) freeze-drying machine, in situ freeze-drying. It has changed the tedious operation in the past drying process, prevented the pollution of materials, and realized the automation of drying sublimation. The machine has shelf heating and programmable functions, can remember the freeze-drying curve, convenient for users to observe the material freeze-drying process.

Features of WK-200F Freeze dryer (Lyophilizer):

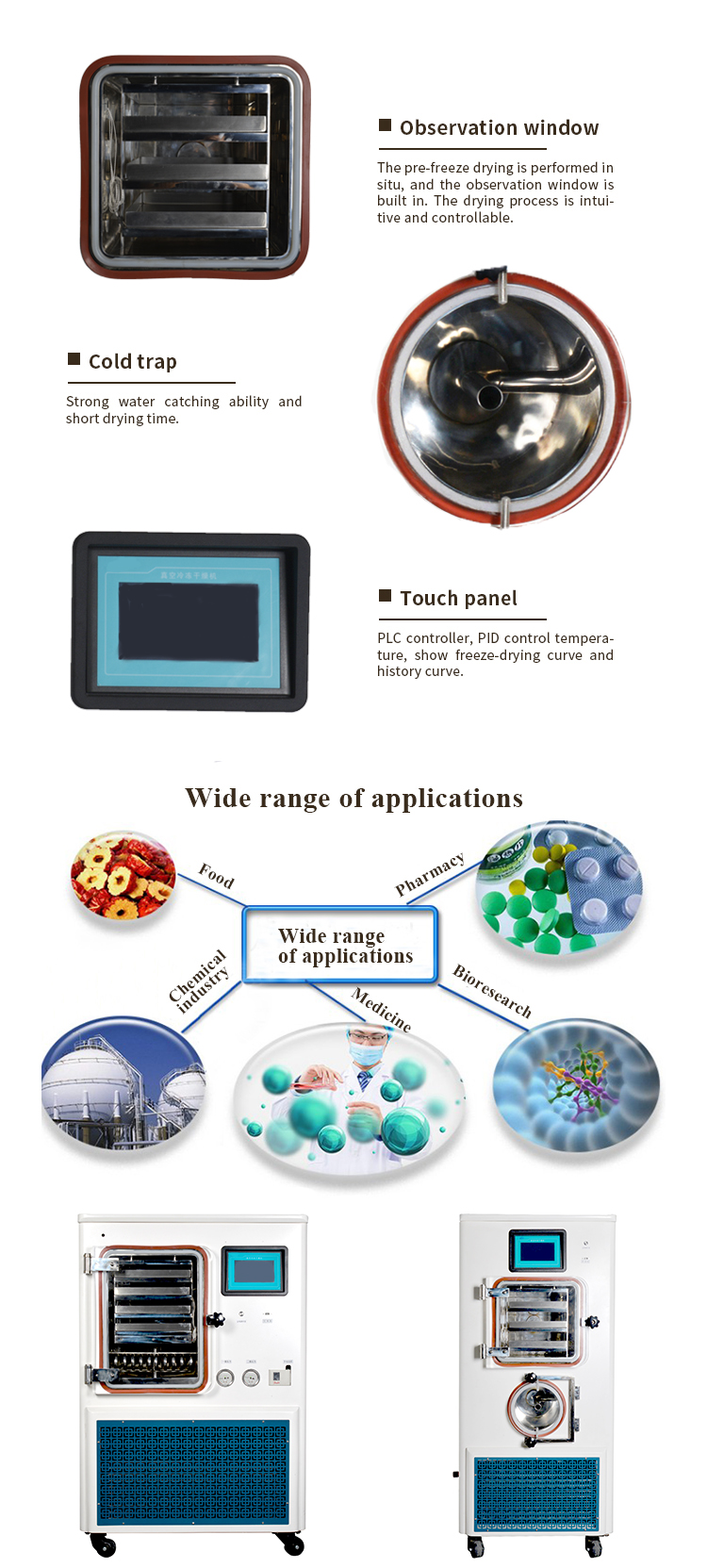

1. Square bin in situ vacuum freeze dryer, pre-freezing, drying in situ completion, easy operation, good drying effect.

2. The door of the drying chamber is made of ACRYLIC material, colorless and transparent, and the whole process of freeze-drying can be observed.

3. The aeration (water discharge) valve adopts safety diaphragm valve, which can be connected with inert gas source. After drying, it is filled with inert gas to extend the shelf life of materials.

4. Specialized gas diversion technology, cold trap ice capture uniform, ice capture ability is strong.

5. Compressor of international famous brand, double duplex refrigeration, high efficiency and energy saving, long service life and low noise.

6. Partition temperature fuzzy control technology, shelf temperature difference is small, high temperature control precision, uniform drying effect.

7. The freeze-drying curve optimization control technology can control the cooling rate in the pre-freezing stage, and control the temperature rise rate of the sample in the sublimation and analytical drying stage and the optional vacuum degree regulation system.

8. Powerful sensor calibration function to ensure the accuracy of long-term use of the measured value.

9. 7inch real color industrial embedded touch screen +SH-HPSC-II modular controller, high control precision, stable and reliable performance.

10. Professionally designed FD-Pilot control system can save hundreds of process formulations, each of which contains 50 temperature control sections to improve the process optimization rate.

11. Intelligent data recording system, real-time record and display cold trap temperature curve, sample temperature curve, vacuum degree curve, the exported data can be scanned and printed by computer and a variety of operations, convenient process optimization and drying effect verification.

12. Flexible manual + automatic control mode, manual for exploring process, automatic for mass production.

13. Real-time alarm display and historical alarm query function, convenient fault diagnosis and equipment maintenance.

14. Can set user level and password, decentralized operation management.

Main parameters:

| Model | WK-100F | WK-200F | WK-300F |

| Capacity | 1m2 | 2.25m2 | 3.15m2 |

| Cooling temperature | <-80°C | <-80°C | <-80°C |

| Vacuum | 10Pa | 10Pa | 10Pa |

| Pumping rate | 15L/S | 15L/S | 15L/S |

| Cooling type | Air cooling | Air cooling | Air cooling |

| Defrost type | Water | Water | Water |

| Total Power | 6.5KW | 13.5KW | 14.5KW |

| Material plate | 6*(355*475*30)mm | 6*(500*450*35)mm | 14*(500*450*35)mm |

| Shelf temperature | -50°C~80°C | -50°C~80°C | -50°C~80°C |

| Shelf number | 7+1 | 7+1 | 7+1 |

| Power supply | 3*380V/50Hz or 220V/60Hz | 3*380V/50Hz or 220V/60Hz | 3*380V/50Hz or 220V/60Hz |

Product details:

We are professional manufacturer!!! We supply turnkey solution for you. If you are interested in our products . Please send us inquiry immediately for price and more information.We will reply you very soon!

- High-tech Zone, Zhengzhou City, Henan Province, China.

- +86 132 9817 7608

- info@rotovap-wellknown.com

- li249869402

Copyright © Zhengzhou Well-known Instrument & Equipment Co.,Ltd. All Rights Reserved Sitemap