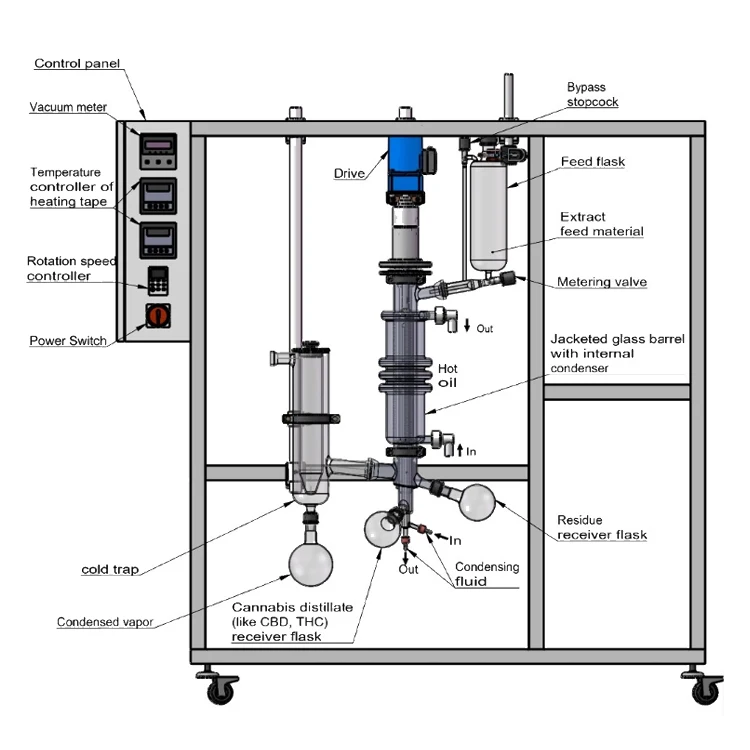

MD-60 lab short path molecular distillation

Lab apparatus short path distillar rolled film evaporator molecular distillation

Molecular Distillation is a special liquid-liquid separation technology, which is different from traditional distillation on the difference boiling point. This is a kind of distillation in high vacuum environment, for the difference of material molecular movement free path, was carried out in the heat sensitive material or high boiling point material distillation and purification process. Short Path Distillation is mainly used in chemical, pharmaceutical, petrochemical, spices, plastics, oil and other fields.

High evaporation efficiency and reduced retention time, with minimal time delay

Short path distillation is made from high borosilicate glass 3.3 and PTFE, which have excellent corrosion resistance

Main body of Short path distillation is made of high borosilicate glass 3.3, allowing the whole process to be observed very clearly

German technology brand frequency conversion deceleration motor, with self-cooling fan, long time continuous working

Magnetic force transmission make film forming system separate from motor, the top sealing of distillation barrel have no dwang through.

The whole System performs a completed sealing. Min Vacuum degree can reach 0.1Pa.

Highest temperature of the system can reach 230℃/300℃, accurate temperature control can be realized

Scraper Model and self-cleaning roller Model film forming system are available

The barrel of the distiller has glass and stainless steel material for selection, and the glass distiller has two forms of half and full package.

| Model | MD-60 | MD-80 | MD-100 | MD-150 | MD-200 |

| Barrel diameter(mm) | 60 | 80 | 100 | 150 | 200 |

| Feeding rate(g/hr) | 500-700 | 750-1000 | 1000-1500 | 2000-3000 | 3000-5000 |

Feeding flask volume(L) Customizable volume as clients' needs | 1 | 1.5 | 2 | 2 | 5 |

| Effective evaporation area(m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

| Motor power | 90 | 120 | 120 | 120 | 200 |

| Maximum speed(rpm) | 500 | ||||

Distillate receiving flask Customizable volume as clients' needs | 1L | 1L | 2L | 3L | 5L |

Residue receiving flask Customizable volume as clients' needs | 1L | 1L | 2L | 3L | 5L |

| Operation temperature | Up to 200℃ | ||||

| Voltage | 220V/50-60Hz | ||||

The above data is for reference only! In conclusion, the two rigid test conditions are

1. a suitable vacuum

2. heat preservation and material properties.

3.(A)means standard model (B) means customized model

4.1 Pa =0.01 mbar≈0.0075 Torr ,5 Pa =0.05 mbar≈0.0375 Torr

- High-tech Zone, Zhengzhou City, Henan Province, China.

- +86 132 9817 7608

- info@rotovap-wellknown.com

- li249869402

Copyright © Zhengzhou Well-known Instrument & Equipment Co.,Ltd. All Rights Reserved Sitemap